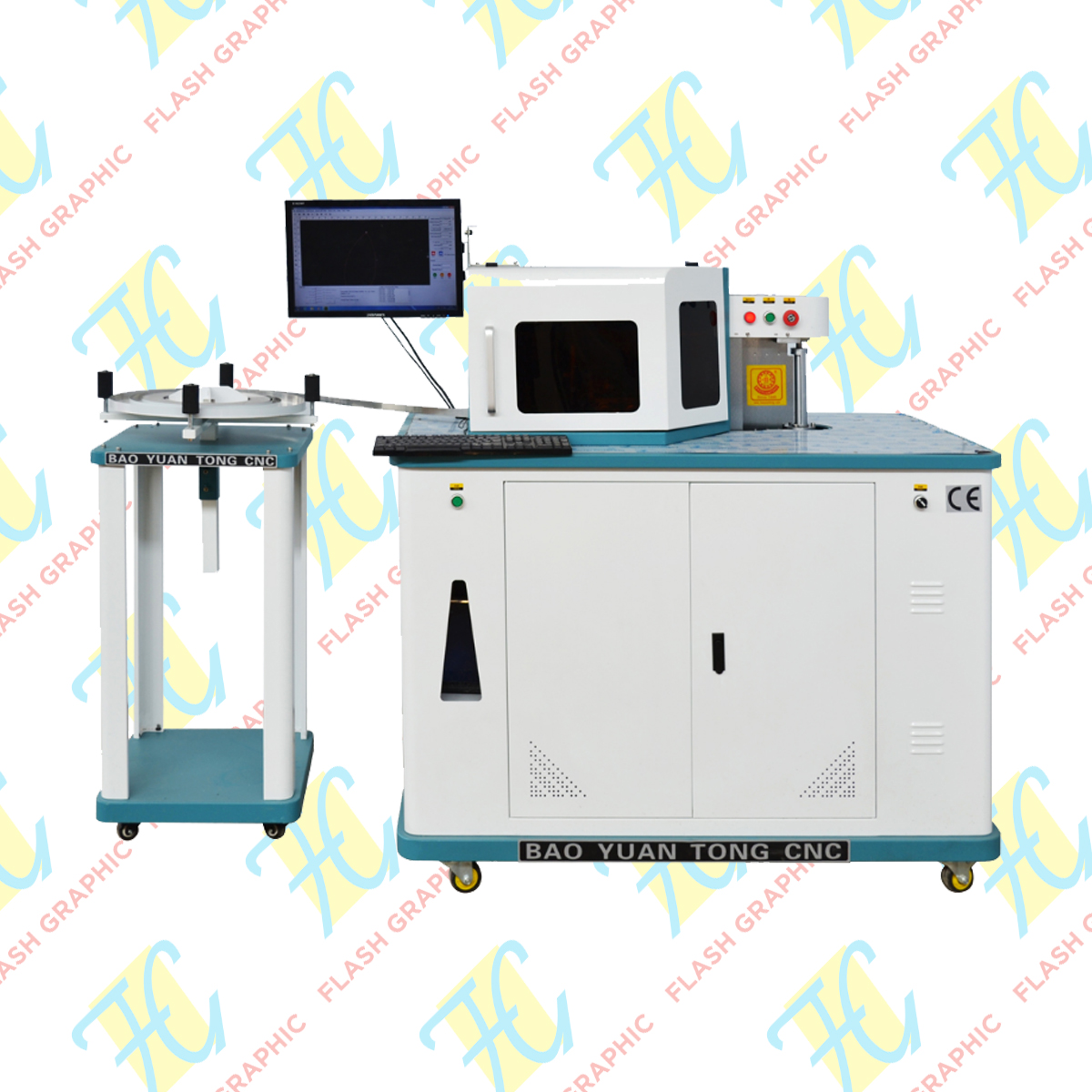

- Multi-function, dual system and dual tool: stainless steel grooves adopt servo motor, aluminum grooves adoptstepper motor. Make the grooving angle more accurate, and extend the machine and tool life; It can save working time, materials and labor costs.

- Servo motor control, Double-bar linkage arc bending device, when bending aluminum materials, adopt double-copper shaft arc bending,double-bar linkage extrusion bending, to ensure that the material surface is not damaged; When bending stainless steel material, adopt double bar linkage to flap the arch, ensure that thicker material canbe processed.

- With an encodé for compensating the lose step of stepper motor,ensure the letters accuracy.

- Set parameters in the software, automatically adjust the length,radian and depth.

- Intelligent software can modify parameters and semi-automatically adjustthe depth of cutting tool.

- Roller friction feeding, front and rear two groups, a total of four groups of rubber covered rollers, with the coder for transmission,more convenient feeding, low noise.

- Lechuang CBS4 control system, simple and fast operation, stable system, simple interface.Easy to learn and operate.

- The smallest arc diameter is 7mm, making the characters more accurate and exquisite.

Avis

Il n’y a pas encore d’avis.